Since the dawn of the industrial revolution, production has followed a linear path of take, make, use, and discard in a system that wastes a majority of resource and energy inputs. While this model is continuously improved for efficiencies, many of the improvements only serve to accelerate the flow of materials and products to the landfill. This is because the linear economic model is fundamentally, if unintentionally, designed to create waste. A wholesale redesign of our materials-based economy is needed and is thankfully emerging.

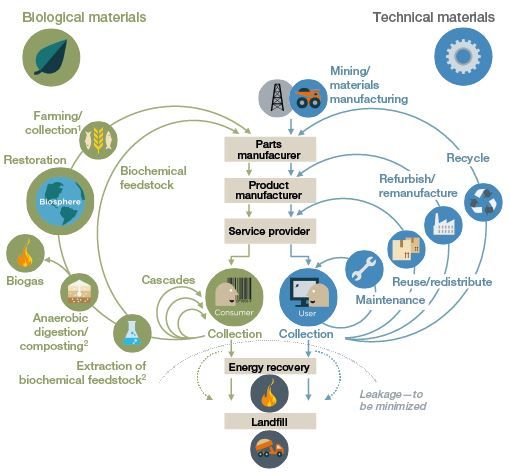

The circular economy (CE) is a relatively new business model that is intentionally and deliberately designed as an interactive system of value-creating and regenerative loops as diagrammed below by the Ellen MacArthur Foundation (EMF).

The most exciting aspect of a circular economy business model is that it is not a doom and gloom scenario of doing less with less. It is economic model that allows for increasing prosperity and access to goods and services, while keeping valuable resources in productive cycles and out of landfills. Collaborative studies commissioned by EMF and led by the management consulting firm McKinsey estimate an annual net material cost savings of up to $630 billion, based on only a subset of the durable goods manufacturing sectors. The studies further estimate as much as $700 billion in savings is available in the global consumer goods market for food, beverages, textiles, and packaging via a shift to a circular business model.

Taking a deep dive into circular economy literature shows that it is a powerful synthesis of several strategies, among them:

- Design for environment (DfE) to include a variety of nontraditional or less common attributes such as modularity, upgrade-ability, refurbishment, disassembly, re-manufacturing, etc.,

- Industrial ecology or symbiosis, which is based on the premise that the waste from one industrial system or process becomes a resource or material input for another,

- Products of service, whereby a producer retains ownership of a product and leases its utility, taking back the asset at end of useful life or when the lessee no longer wants or needs it; then upgrading, refurbishing or re-manufacturing it into a next generation service-product,

- Reverse logistics, the process by which products and materials are effectively collected and maintained in a closed loop supply chain.

While not explicitly called out in the CE literature, sustainable materials management (SMM) offers another possible pathway to a closed loop business model. Since materials of all types are the basis of our global consumptive economy, SMM provides the critical building blocks that can enable a company to prepare and position itself to become a CE business.

At GreenBlue we promote the adoption of SMM practices to help companies become more sustainable enterprises based on three core principles: Use Wisely, Eliminate Toxicity and Recover More. All three are tied to design, which is the most critical element in a circular economy. Use Wisely governs the selection, sourcing, and optimization of resources and sets the stage for re-utilization. Eliminate Toxicity, removes potential barriers to product recovery, component separation and material revalorization, ensuring those molecules can stay in play in either a technical or biological cycle as depicted in the EMF diagram, above. Recover More requires development of the technologies and infrastructure, to track product assets, collect and efficiently transport them to a revalorization facility. As companies become adept at these three core principles they can develop design strategies, industrial synergies, logistics, information, financial accounting systems, and performance metrics that will allow them to make the ultimate paradigm shift to a fully circular business model.

Watch this blog for further discussion of the three core principles and building blocks as GreenBlue proceeds to develop a detailed roadmap and rigorous step-by-step implementation framework for best sustainable materials management practices.