Sustainable Packaging Coalition annual conference encourages dialogue and collaboration among leading brands, government agencies, and NGOs

The Sustainable Packaging Coalition’s members-only conference, SPC Advance, provided a forum for industry to engage in dialogue and education on a number of important issues affecting packaging sustainability, punctuated by a lively debate on legislation banning plastic shopping bags.

Nearly 200 attendees from every major stakeholder group convened in Charlotte, NC to address topics including Federal Trade Commission compliance, Extended Producer Responsibility, and the recent wave of local and regional regulatory requirements for foodservice packaging.

The debate on bag bans provided the highlight of the conference, with Marcus Eriksen from 5 Gyres providing a compelling set of arguments to support the environmental rationale for banning plastic shopping bags and Phil Rozenski from NOVOLEX delivering a counterpoint with an equally convincing presentation to persuade the audience that plastic bags have their place in a sustainable materials economy. After both presenters delivered their arguments, a robust Q&A and discussion revealed that common ground exists between environmental activists and the packaging industry: the SPC’s How2Recycle labeling system, which both parties agree facilitates and encourages consumer recycling behaviors. The conference provided a forum for many contentious issues facing the packaging industry, but the collaborative atmosphere fostered more discovery of common ground than widening of divides.

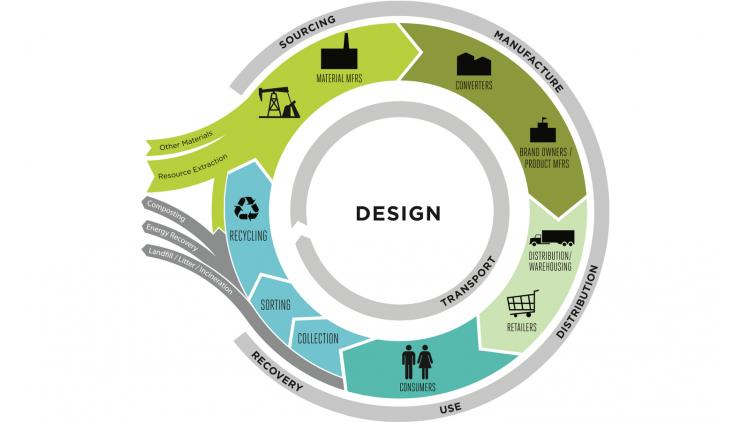

The program at SPC Advance was not restricted to controversial issues, however, and attendees were offered numerous opportunities to engage in collective work to move the needle on today’s opportunities in sustainable packaging including recovery of hard-to-recycle plastics, the role of packaging in the recently popularized concept of the Circular Economy, and the sustainability considerations for pharmaceutical packaging. Attendees heard from several leading business thinkers, highlighted by an energizing keynote presentation from Domtar CEO John Williams, who reminded the audience that “You should tell your own sustainability story in your own authentic way to the audiences that you care most about.”

Networking and education remained a mainstay at SPC Advance 2016, and attendees found ample opportunities to make new connections and reflect on the content of the program at activities including a catered rooftop pool reception, a pub crawl through downtown Charlotte, and tours of material recovery facilities and fiber-producing woodlands. By the end of the conference, SPC Advance attendees were left with new connections, new ideas, and a deep appreciation for the confluence of environmental activism, voluntary industry initiatives, governmental regulation, and the future of sustainable packaging.

.

.