The Sustainable Packaging Coalition recently took a stance against the use of biodegradability additives in petroleum-based plastics. This blog is one in a series of articles about various biodegradability topics and concepts.

Plastic pollution in the ocean is a growing global crisis. It goes by many names; plastic smog, ocean litter, marine debris, and marine pollution are all terms to describe the estimate that eight million tons of plastic find a way into the oceans every year, according to Science magazine. That’s as if one garbage truck dumped its contents into the ocean every minute.

Once plastic is in the ocean, the waves churn it, the sun shines on it, and other variables like temperature and oxygen levels cause the plastic to break into pieces. Those pieces get fragmented further, and those get fragmented, and so on; eventually there’s millions, billions, trillions(!) of tiny plastic pieces (called ‘microplastic’).

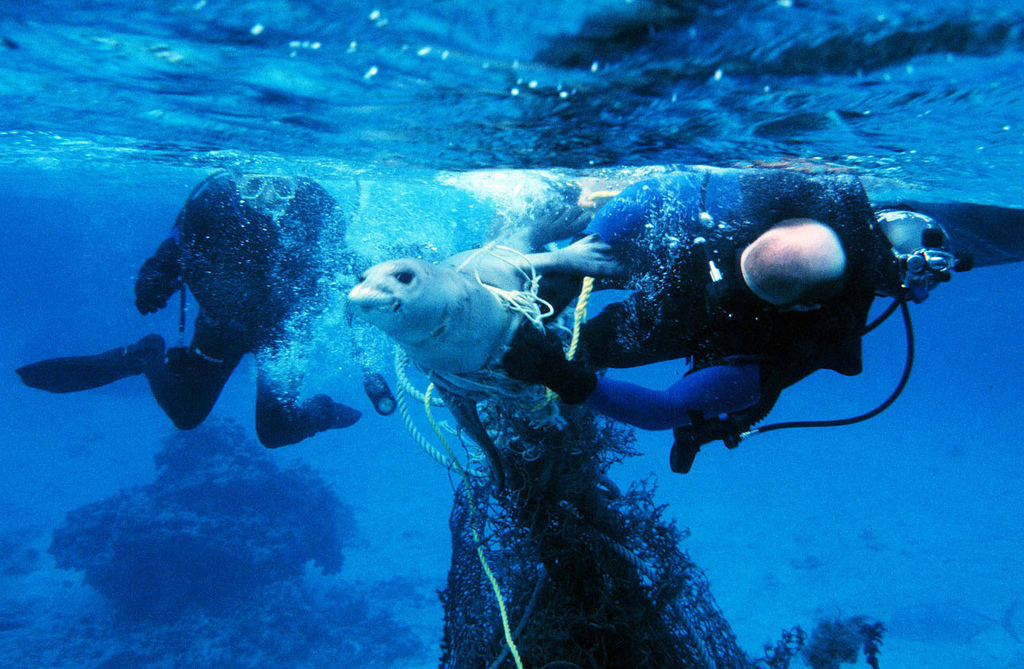

Microplastic is ingested by hundreds of species of ocean animals, including zooplankton, salmon, seabirds and fish. They ingest it by accident or mistake it for food. Before the plastic even becomes small enough to get inside ocean animals, it can entangle and kill or hurt them. This has serious potential to cause significant harm.

Given these facts, it’s rational to ask, “can we fix this problem by adding something to make plastic biodegradable?” You’d think that this would be a brilliant human solution, to make it all magically dissolve in the seawater! Something called ‘biodegradability additives’ would seem to precisely do that job, but unfortunately, it’s not quite that straightforward.

Biodegradability additives enable or encourage biodegradation of petroleum-based plastic. They are sometimes marketed as a solution to litter, particularly in the developing world. One class of additives (often called “landfill biodegradable additives”) function by encouraging the few types of microbes that naturally biodegrade petroleum-based plastics. The other class of additives (“oxo-degradable” or “oxo-biodegradable”) function, ironically, by expediting the plastic’s ability to fragment into smaller pieces.

Unfortunately, biodegradability additives cannot improve the ocean pollution problem for several reasons. First, plastic products and packaging that contain these additives tend to be marketed as “biodegradable,” but that tells us nothing about the environmental conditions necessary for biodegradation, the time frame necessary for biodegradation, or the impacts that may occur before biodegradation is complete. To make matters worse, the word “biodegradable” on packaging may encourage littering of that material. Further, the additives are designed to work slowly, at best, and still present a significant risk to ocean animals in the interim years before the biodegradation process is complete.

‘Biodegradable’ means something much more limited than what most people would think, and people are more likely to litter items marked as biodegradable.

One problem with biodegradability additives is that the term biodegradable doesn’t often live up to its ideal. The concept of biodegradability suggests that nutrients will harmoniously be given back to the earth at the end of the material’s life — and as the UN points out, there are certainly commercial interests at play in marketing this idea. However, just because something’s called biodegradable, it doesn’t mean it will break down in a reasonable amount of time — especially if it’s in a place it’s not designed to be, such as the ocean.

Biodegradability is a highly relative concept. Most packaging that is designated as “biodegradable” has passed one of several ASTM tests for biodegradability, each of which features unique test conditions designed to mimic parameters at specific environments such as a bioreactor landfill (ASTM D7475) or an anaerobic digester (ASTM D5511)—not to be confused with compostability standards, which are different and more stringent.

These are very different environments, in terms of heat, oxygen and other factors, than a place like Lake Michigan or the Gulf of Mexico. In other words, a material that has passed one ASTM test should not be assumed to be biodegradable in every environment—especially a marine environment. There’s only one standard for biodegradability in the marine environment (which is currently being revised), but petroleum-based plastics with biodegradability additives have been unable to meet that standard. Considering all these variables, the term “biodegradable” as applied to petroleum-based plastics actually means something much more narrow and limited than what most people would probably ever imagine.

Not only do petroleum-based plastics with biodegradability additives fail to meet marine biodegradability standards, but it also makes people more likely to litter something if it’s labeled biodegradable, as Keep America Beautiful discovered in a study in 2009. The UN points out that this behavior allows for the potential for ocean pollution to become worse.

Biodegradability additives do not mitigate harm to ocean animals; they are still subject to serious risk in the time before petroleum-based plastic starts to biodegrade.

Here’s something else to consider: plastics with biodegradability additives are not designed to even commence the biodegradation process for years, sometimes as many as five. Even if these plastics were theoretically able to meet the standard of marine biodegradation (which specifies that at least 30 percent of the material’s carbon content must turn into carbon dioxide within 6 months), the plastic would still present a threat in that interim time to ocean animals through ingestion, entanglement, or potential toxic exposure.

Hundreds of species of ocean animals have been known to become entangled by plastic, such as in fishing nets in the photo below. If biodegradability additives are added to petroleum-based plastic fishing nets as the solution to that problem, it causes people to feel a distorted sense of comfort that could encourage more litter. Besides, if it takes years for the biodegradation process to start anyway, that doesn’t help a seal caught in one of those nets today.

Ocean animals are also found with plastic in their stomachs, causing starvation. If the average lifespan of a salmon is 3 to 8 years, and it could take more than 5 years for a petroleum-based plastic with these additives to biodegrade, that won’t help the salmon who are accidentally eating it and experiencing harm to their bodies during their lifetimes.

Beyond these serious concerns, a limited number of scientific studies have explored whether ocean animals could be subject to potential toxic exposure when plastic gets inside of them. Studies demonstrate that microplastic is a carrier for toxic pollutants in ambient seawater. In one study, twelve seabirds were examined; all twelve had microplastic in their stomachs. When they looked closer, they found PBDEs (flame retardants applied to plastics and textiles) on the surface of the microplastic. Further science is required to explore if and how those toxins carried by plastic have the potential to migrate into the animals’ body tissues.

If future scientific studies confirm that migration of toxins into animal tissue does occur, then the impacts up the food chain could be immense. Bioaccumulation of toxins via microplastic is a theory that is only recently being studied. If real, it could not only have dangerous repercussions for ecologically significant species, but also for the seafood industry and human health.

Reducing the number of years that it takes for a plastic to biodegrade creates a false sense of security and could aggregate the plastic pollution problem facing our world’s waters. For this reason, biodegradability additives for petroleum-based plastic are an ineffective band-aid to the ocean pollution problem.

Instead, what we need are solutions that prevent plastic from becoming litter in the first place. We need solutions that reconceptualize how materials should flow through our society, and how technology and infrastructure can evolve to address these issues. We should develop systems that encourage packaging design to be intimately intertwined with the sourcing of recycled materials and how waste management systems operate. For example, it’s better to design packaging that is easier and more valuable to recycle, so that we can keep materials in perpetual use rather than throwing them away. Related to that idea is the need to encourage our culture to perceive waste as a resource instead of a problem.

The Sustainable Packaging Coalition (SPC) released a position paper outlining the environmental harm that results from these additives.

The SPC seeks to continue the collective work of industry and NGOs to achieve the beneficial end-of-life solutions necessary for the sustainable use of plastics—it’s just that biodegradability additives is not one of them.