The SPC Executive Committee serves as an advisory group to The Sustainable Packaging Coalition. The EC’s role is to provide advice, act as ambassadors for SPC/GreenBlue, and make recommendations on issues related to the SPC, including its goals, strategies, and projects.

We interviewed our three new Executive Committee members, Liza Blackwell (Nike), Kim Carswell (Target), and Chris Davidson (WestRock) to learn more about them and what they hope to accomplish while serving on the SPC Executive Committee.

EC member name: Christopher Davidson

EC member name: Christopher Davidson

Title: Director, Corporate Sustainability

Company: WestRock

Q: When and how did you get into forestry?

I grew up in both England and Jamaica and I was very interested in fishing so I spent a lot of time outside. I went to high school in Jamaica and as I got closer to graduation, I realized I wanted to do something other than, what was in my mind, the typical career path. I was introduced to forestry at a local career fair; they handed out a pamphlet that described different careers, one of which was forestry. That led to me getting a summer job with the Forestry Department, and that experience is what really finalized it for me in terms of deciding I want to become a forester”.

Q: And, from there, how did you get involved in the pulp and paper industry?

I actually started out with plans to work in the industry once I graduated. However, as I got closer to the graduation date for my bachelor’s degree I made the decision to just continue on and go straight into a masters program. At that point I wanted to become an educator, a professor. But my plan was to first go out and get some actual industry experience, then go back, get my PhD and teach. After I finished my masters, I worked in Florida as a land management forester for about 3 years before heading to Virginia Tech to work on my PhD. But I did it in a non-traditional way, working as a research associate full-time and working on my degree part-time, so it took me about 6 years. When I finished I was offered two industry positions and a teaching position at a smaller university. The university was focused on teaching and I really wanted to work at a research institution, so I told myself ‘I’ll just work for a few more years and get some more industry experience, then I’ll and come back to academia’, but as you can see, I’ve stayed in the industry, and it’s been a great decision for me.

Q: Where do you see the most opportunity for sustainability in the private sector? For sustainable packaging?

From a business perspective, there’s more opportunity because brand owners are becoming more educated about sustainability. There’s a greater willingness to partner and work with companies now. You see partnerships today that you would have never seen 10 years ago – forest industry working with brand owners and NGOs on issues that in the past, they were on opposite ends of the spectrum. I think there’s a recognition today that there’s greater opportunity, and greater benefits, if companies, brand owners and other stakeholders work together to try to solve problems, whether it’s on the raw material side or dealing with social issues around sustainability.

Q: What has drove WestRock to join SPC? And what in particular inspired you to run for the SPC Executive Committee?

We are a global packaging company and we make many different types of packaging. The majority of it is wood fiber-based packaging but a part of our business is making plastic caps, closures, and triggers. We are also packaging designers, we make partitions and displays, and we have a recycling business.

We know that the SPC is a well-regarded organization, and it’s a great opportunity to learn about what’s happening in the packaging space globally. Our vision is to be the premier partner and unrivaled provided of paper and packaging solutions globally. That means we need to understand exactly what our customers want, what consumers think about packaging, and potentially, what’s on the horizon. For us, working with an organization like the SPC helps us in each of those areas, it’s as simple as that. I consider myself to be a neophyte on the EC in terms of my packaging experience but I think I bring a lot to the table in terms of my industry experience regarding the raw materials that are used in much of packaging today. I really wanted to be able to develop a greater understanding of the packaging space as well as to continue to help the SPC develop projects and programs that the members find useful.

Q: What would you like to achieve during your time on the EC?

If there were one thing that I would like to be instrumental in achieving during my time on the EC, it would be broadening the understanding of what sustainable packaging means. And by that I mean if you were to go out today and go to a supermarket and ask 10 different people what sustainable packaging means to them, you would probably get 10 very different answers. Much of our packaging is wood-fiber based and there’s a lack of understanding of the benefits of using this particular resource for packaging. I’d like to think that I could potentially help SPC broaden that understanding, not only among the membership base amongst brand owners and consumers as well.

Q: What SPC product are you most excited about?

Well there are a couple, I think the foodservice ILC, obviously forest certification interests me, and then the How2Recycle Label. Working for a company with a recycling business, it’s very clear that one of the limitations to recycling is getting people to put the right thing in the right box, so the How2Recycle label and potentially the How2Compost label is very exciting as well.

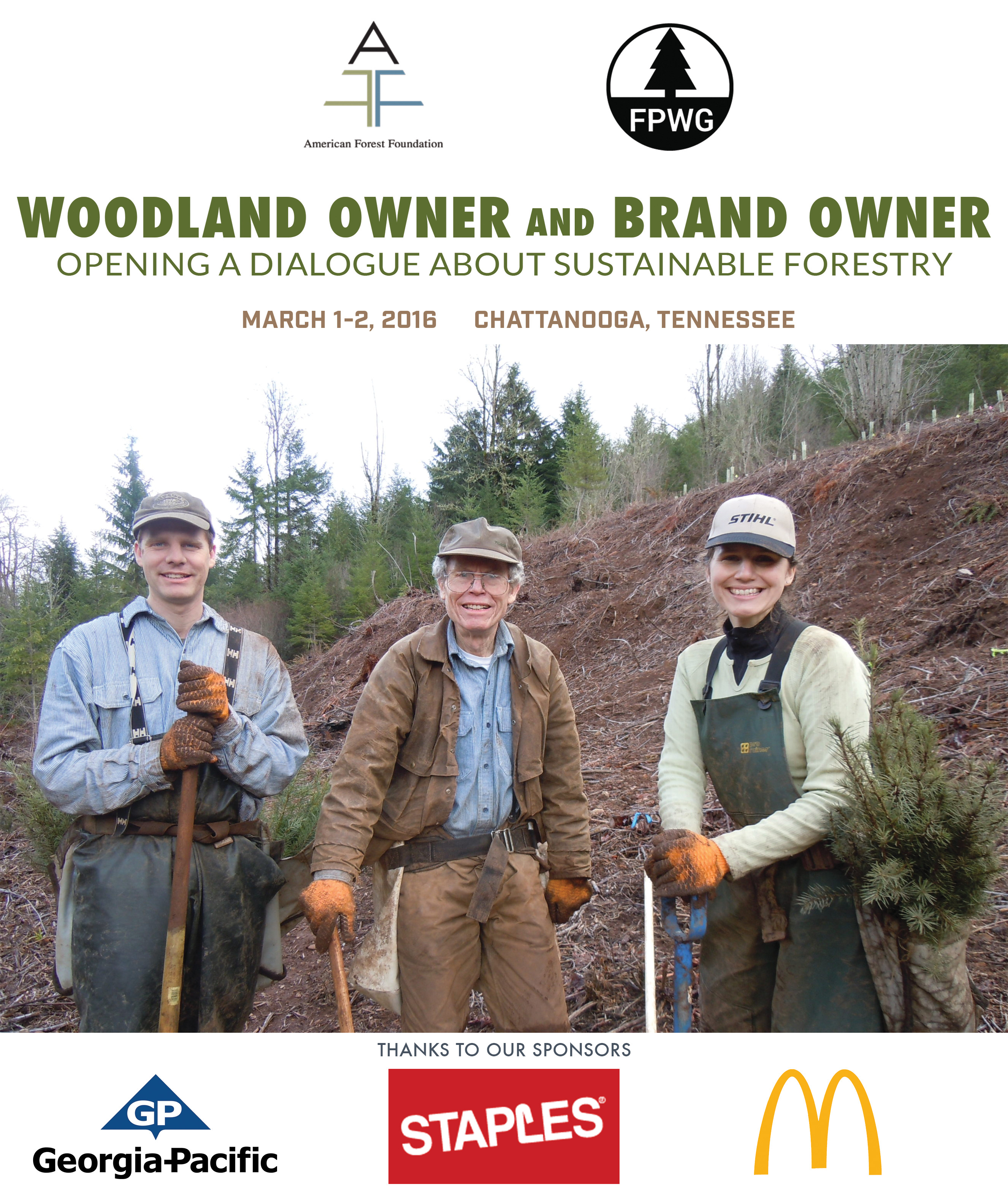

To kick off the Summit, woodland owners described why they each owned land, noting family legacy, income, and a love of nature. Responding to questions from brand owners, they also described challenges they face such as insects and disease, natural disasters like wildfire and hurricanes, high management and property costs, and declining markets. Concerns about trust, and the future of the land as it is passed on to future generations were voiced as well.

To kick off the Summit, woodland owners described why they each owned land, noting family legacy, income, and a love of nature. Responding to questions from brand owners, they also described challenges they face such as insects and disease, natural disasters like wildfire and hurricanes, high management and property costs, and declining markets. Concerns about trust, and the future of the land as it is passed on to future generations were voiced as well.

EC member name: Liza Blackwell

EC member name: Liza Blackwell Q: Nike was a found member of the SPC in 2004, over 10 years ago. What inspired Nike, and you, to get involved with the SPC?

Q: Nike was a found member of the SPC in 2004, over 10 years ago. What inspired Nike, and you, to get involved with the SPC?