As more companies incorporate environmental sustainability into their business practices and long-term corporate goals, there are often trade offs and compromises between environmental and economic desires. A company’s primary drivers may or may not align with environmentally beneficial choices, and companies often straddle that delicate line between seemingly incompatible objectives. Ideally, they end up going for the best possible choice that meets both their economic and environmental desires, as well as their consumer’s needs.

Recently, Aristocrat Vodka unveiled their new bag-in-box (BiB) packaging design, which uses a plastic pouch and spout housed within a waxed cardboard box. The benefit of the BiB design is that the packaging holds more than double the volume as their traditional 750 ml bottle, so shipping becomes more efficient by volume, which may result in better fuel efficiency. Typically, the BiB design – commonly used for dispensing large volumes of liquids – consists of a flexible plastic pouch or bladder with a plastic spout housed within a corrugated cardboard box. The wine industry noticeably popularized this packaging in the past few decades. Companies have issued LCA studies for BiB packaging in comparison to other conventional packaging option for liquids – including PET bottles, LDPE bottles, aseptic bottles and glass bottles – and many studies have concluded that BiB packaging is environmentally competitive, and in many cases superior to, other commonly available packaging formats. Also, BiB packaging makes wine and other spirits a feasible option for large outdoor events, particularly if glass is prohibited. It’s generally viewed as a sustainability success when BiB packaging eliminates bulky materials, ships more efficiently, and adds consumer value.

Recently, Aristocrat Vodka unveiled their new bag-in-box (BiB) packaging design, which uses a plastic pouch and spout housed within a waxed cardboard box. The benefit of the BiB design is that the packaging holds more than double the volume as their traditional 750 ml bottle, so shipping becomes more efficient by volume, which may result in better fuel efficiency. Typically, the BiB design – commonly used for dispensing large volumes of liquids – consists of a flexible plastic pouch or bladder with a plastic spout housed within a corrugated cardboard box. The wine industry noticeably popularized this packaging in the past few decades. Companies have issued LCA studies for BiB packaging in comparison to other conventional packaging option for liquids – including PET bottles, LDPE bottles, aseptic bottles and glass bottles – and many studies have concluded that BiB packaging is environmentally competitive, and in many cases superior to, other commonly available packaging formats. Also, BiB packaging makes wine and other spirits a feasible option for large outdoor events, particularly if glass is prohibited. It’s generally viewed as a sustainability success when BiB packaging eliminates bulky materials, ships more efficiently, and adds consumer value.

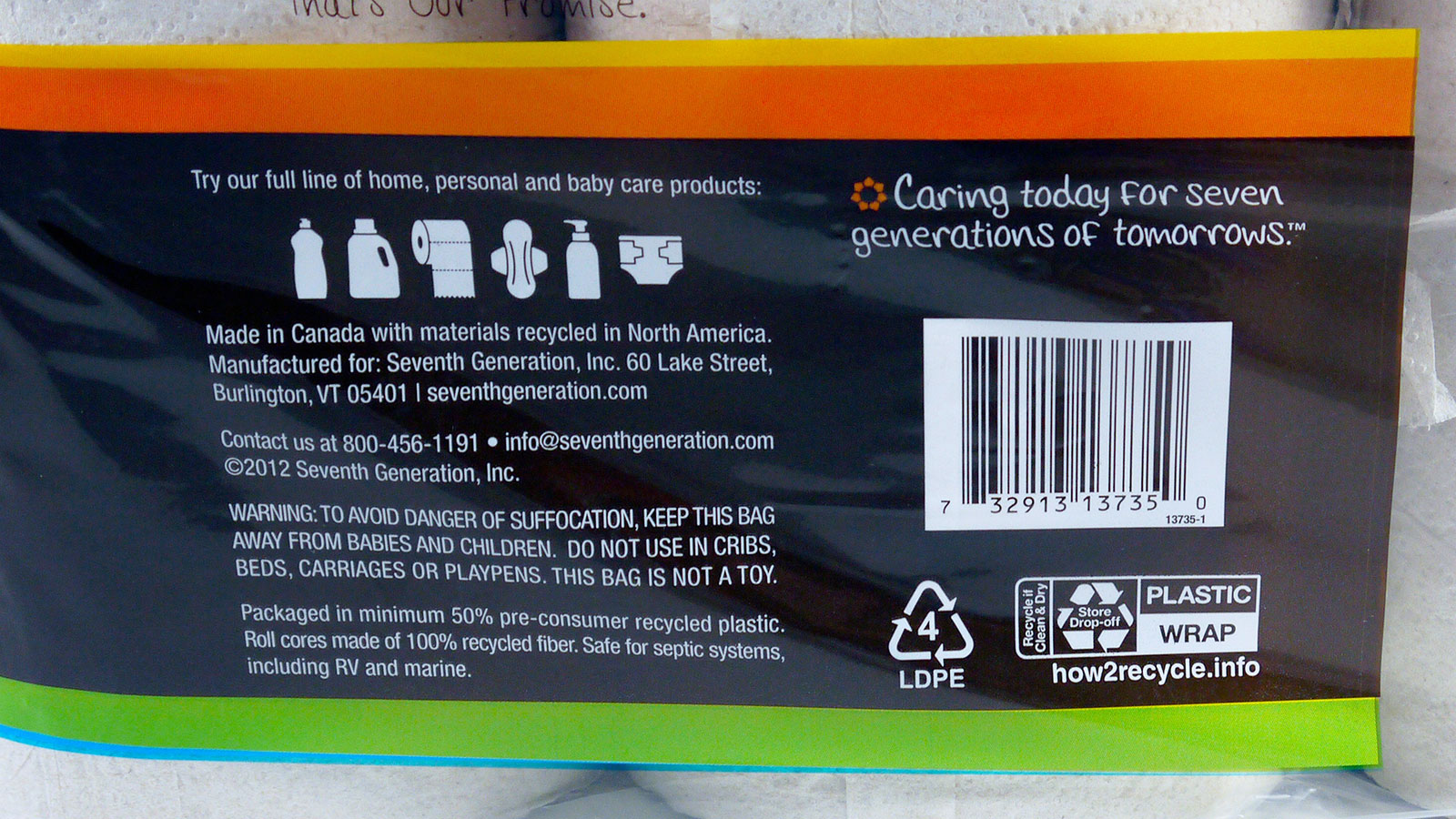

But the individual components of the package reveal a more nuanced narrative in the switchover from the plastic bottle to the BiB package. On one hand, the plastic pouch uses less material, contributing to an overall reduction of plastic, but the caveat is that the flexible plastic pouch is not as widely recyclable as the plastic bottle in most communities. The flexible plastic pouch in the BiB packaging is a composite #7 plastic, whereas the plastic used for the traditional 750 ml bottle is PET, which is more widely accepted and recycled across the country. In 2013, EPA concluded that about 29.8% (75.8 million tons) of the MSW stream is packaging waste. Of that, about 18% (13.98 million tons) is plastic packaging waste and 27% (3.78 million tons) of all plastic packaging waste in the MSW stream is flexible plastic wraps, bags, and sacks. The majority of flexible packaging waste ends up in landfills because it’s often composed of multiple resins that are difficult to separate and because recyclers do not have the capabilities to accurately capture composite films and pouches.

Just as important to BiB packaging as the plastic pouch interior, the material of the exterior shell contributes to a package’s overall recyclability. However, unlike boxed wine packaging that uses a clean, corrugated cardboard exterior that’s fully recyclable, Aristocrat Vodka chose a waxed cardboard exterior. What are the benefits of this design? Waxed cardboard, which has been treated, coated, or saturated with wax, provides a waterproof barrier for moisture control. This feature allows consumers to either freeze or fill their boxes with ice to chill the product to temperatures more suitable for consumption.

While the chillable packaging offers consumer convenience, waxed cardboard is not considered recyclable by the majority of paper mills across the country because non water-soluble wax coatings will eventually create problems in the repulping process. While paper mills can handle a small amount of wax, they generally prefer clean cardboard and paper that is free of coatings, films, and liners; these substances will adhere and persist through the pulping process, impacting the longevity of mill equipment and contaminating the final product. From a market standpoint, it’s more challenging for a paper mill to produce high-grade product when the feedstock includes waxed cardboard that can cause imperfections, particularly when the residual wax and additives decrease tensile strength and reduce tear resistance. Wax chips also result in spots and can inhibit inks from drying properly on the final product. Since paper mills prefer clean corrugated cardboard, many communities have explicitly banned waxed cardboard from their recycling collection stream.

Fortunately, waxed cardboard is recoverable as organic waste and useful as feedstock for backyard composting. Additionally, there are new technologies that allow paper mills to process waxed cardboard, including a series of washers that separate a significant amount of wax. But access to these technologies and facilities is still largely limited. While 47 alternative wax coatings currently available on the market have undergone testing by the Fibre Box Association to be deemed “recyclable”, wax alternatives still have some limitations. They often only mimic certain characteristics of standard wax coatings, and they may not meet all performance criteria (temperature, moisture, light, oxygen) in the same way that standard wax meets all these criteria across the board. Nevertheless, recyclability of the BiB packaging could be improved if it used an alternative wax coating. Until economic feasibility exists for expanded use of these wax-processing technologies and wax alternatives, manufacturers, brand owners, and consumers should expand their knowledge about beneficial disposal options for waxed cardboard.

BiB packaging certainly facilitates more efficient shipping and offers certain consumer benefits such as portability. Despite the potential benefits, Aristocrat Vodka’s BiB package is a lost opportunity to offer a recyclable package. It’s encouraging that a major brand like Aristocrat Vodka is pushing for creative packaging that could move the liquor and spirits market toward more widely utilized sustainable packaging options, but work remains to pinpoint the best solutions that meet environmental sustainability, economic preferability, and consumer needs.