Every day, we are exposed to hundreds of chemicals–in the clothing we wear; the detergents that wash them; the food we eat; the cosmetics we apply to soften our skin; the drinking water from our taps… the list goes on and on. Just in the last 50 years, chemists have developed more than 50 million synthetic chemicals, and about 2,000 new chemicals are introduced each year.

Exposure to chemicals begins long before babies are born, and continues throughout their lives. Yet, of the thousands of chemicals in use today, only a small fraction have been tested for their potential hazards as cancer causing agents, as bioaccumulative compounds, as environmental toxicants etc. Currently, hazard information for chemicals used in industry remains poorly regulated, and as a result, major information gaps exist when trying to make informed product design decisions. Without a better understanding of chemical hazards, effectively assessing the potential risks to human and environmental health is difficult.

Regulatory Compliance-Based Hazard Evaluation

Do you know the hazardous chemicals associated with the products you use? Do you know if the company who makes those products is aware of them? Do you care? Our answers may vary, but for the product makers, such questions are essential to putting products in the market that are deemed safe. To assess chemical safety, we need to to understand both the hazards of substances and the estimated level of typical exposure to those hazards. This is the basic formula for figuring out the risk associated with a given substance. Yet, the number of chemicals that have known hazard profiles is quite small in a universe of chemicals used to manufacture all kinds of products.

Using a List of Lists

Much of current chemical hazard compliance is based on if the substance is found on a restricted substances list (RSL). RSLs of known substances of concern exist in many forms and are typically adjusted for a specific industry sector or product category. Examples of authoritative lists are those published by the European Union’s REACH – Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) program, California Proposition 65, US EPA Toxic Substances Control Act (TSCA) Chemical Substance Inventory, and more. In all, there are over forty such lists from national and international regulatory sources, influential NGOs, and scientific bodies.

So, with all these lists, surely we know the relative hazards involved in product production. Well, that depends on the comprehensiveness of the lists to capture all the chemicals of concern for each of the specific hazard endpoints (e.g., carcinogenicity, reproductive toxicity, etc.). This assumes that RSLs are sufficient to capture all hazardous substances used in industry. Unfortunately, this is not the case for commonly used chemicals, not to mention the hundreds of new chemicals that are introduced into commerce every year.

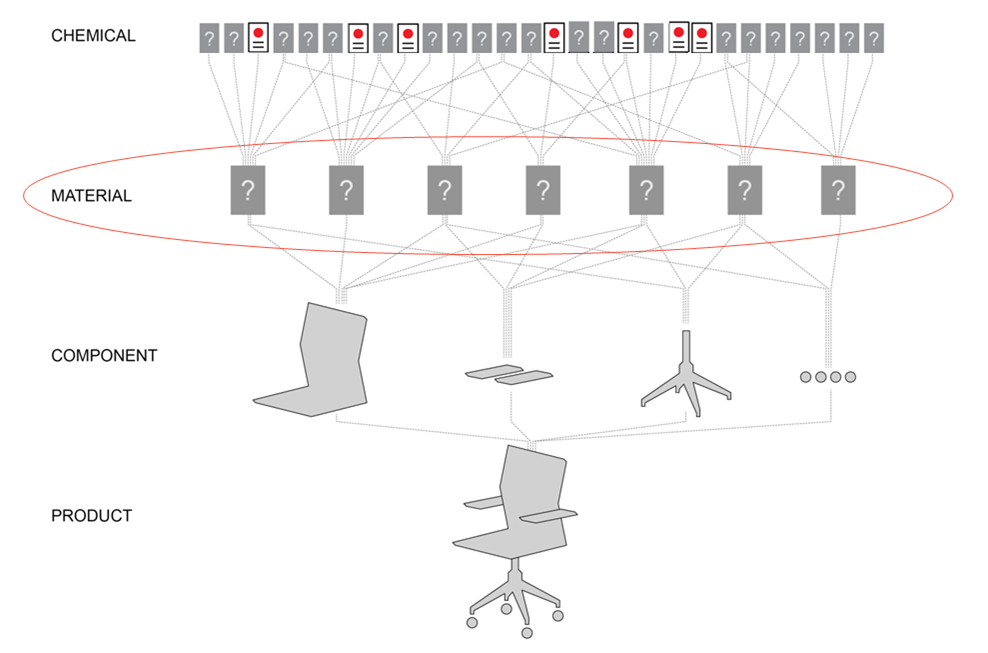

Screening a bill of substances (BOS) or a bill of materials (BOM) for a product against the known lists must be able to identify substances of concern that aren’t on the lists–a conundrum when relying on a relatively static set of lists to identify potential hazards in a world of rapid product innovation. For instance, if a substance has cancer causing potential, but it doesn’t yet exist on any lists, how are we supposed to identify the hazard and evaluate the potential risk of using the substance? The illustration below shows how relying on the list of lists can leave significant gaps for complex products. Notice the extensive data gaps represented by the question marks:

Casting a Wider Net

The compliance-based model relies on lists of known substances of concern, which doesn’t tell the full material hazard story as chemical and material innovation outpaces material health legislation. Keeping pace with material and product innovation requires a system that goes beyond compliance to characterize material constituents; is able to select materials and components that meet long-term sustainability of the brand.

More in depth screening techniques are needed to complete the picture in the above scenario. And, additional tools are needed to provide material manufacturers a forum to share their formulation data, while maintaining confidentiality, and providing third-party verification to material users – the finished product makers – to confidently make decisions that limit exposure and lower risk.

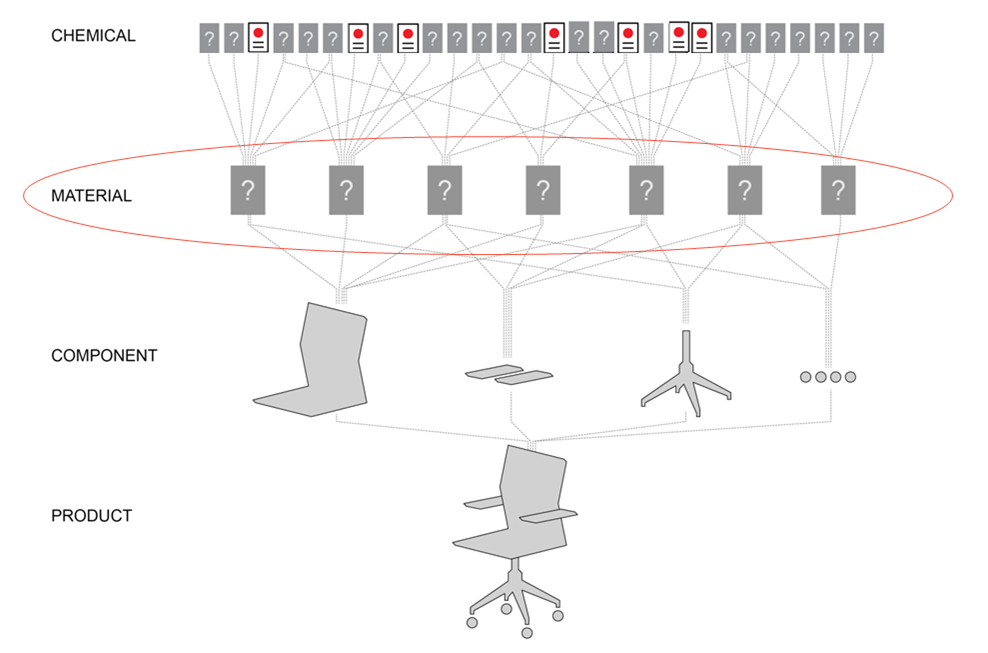

Screening techniques that go beyond compliance-based lists exist, and are used by leading brands to gain knowledge about the material composition of their products. Utilizing more comprehensive screening methods such as SciVera Lens – GHSplus or GreenScreen® for Safer Chemicals can provide a fuller picture of chemicals involved and feed the innovation process, allowing for more intelligent design outcomes. The image below illustrates a more rigorous screening of the BOM that captures a greater portion of the chemicals in use, thus reducing data gaps and enhancing design decision making.

Data Transparency and Clarity

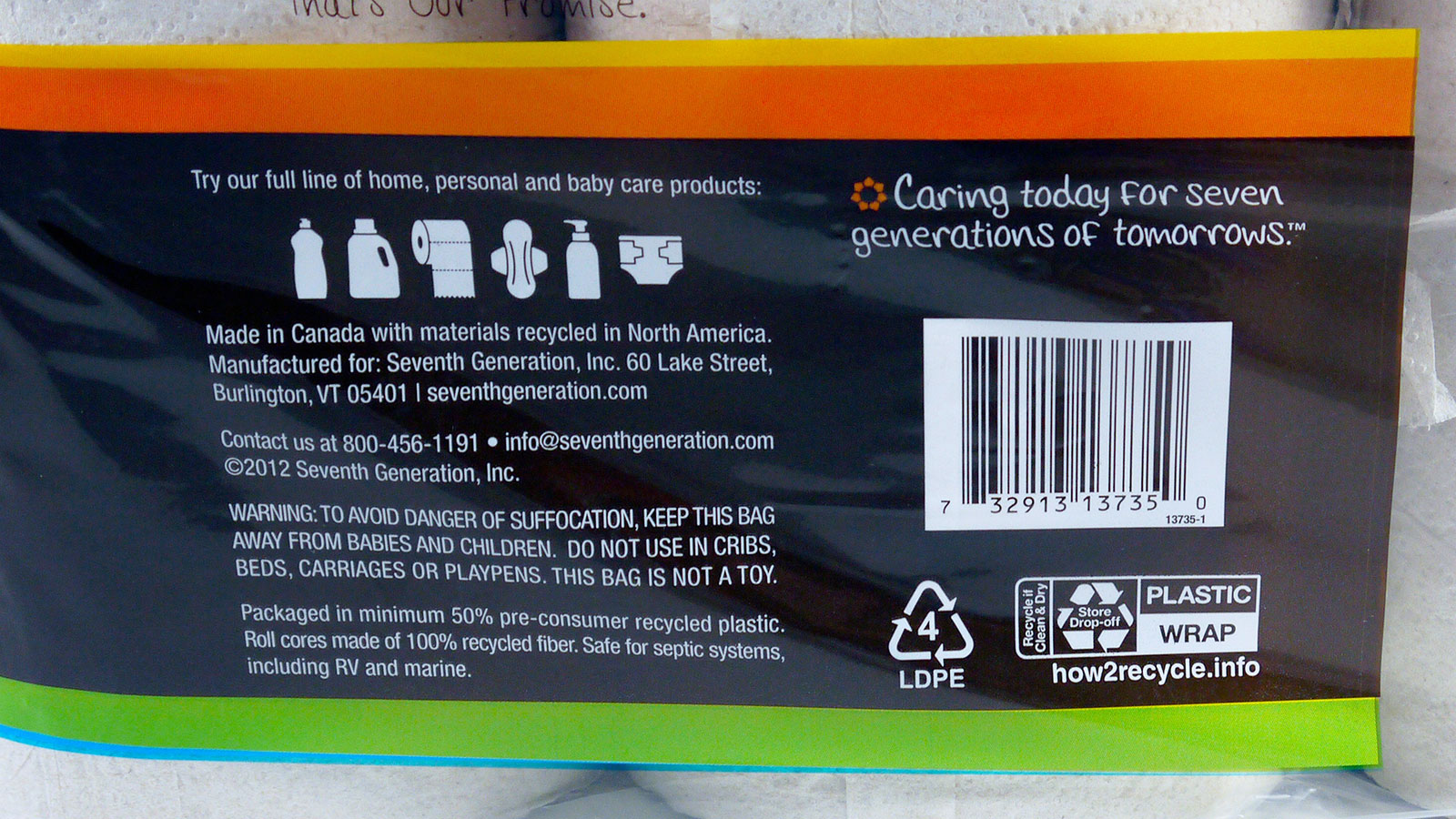

Significant efforts are underway across various industry sectors including outdoor products, apparel and footwear, building products, food packaging , electronics, and others to quantify the life cycle impacts of materials used in consumer products. Material health concerns are, increasingly, becoming part of many of these initiatives, with varying degrees of emphasis.

In response, GreenBlue’s Material IQ provides a platform for sharing material intelligence between material suppliers and their downstream customers. Material IQ™ offers human and environmental health data, standards/eco-certifications, and key sustainability indicators, all in one place. Material IQ can level the playing field for material health data by:

- Significantly reducing data acquisition costs

- Providing valuable information via a consistent evaluation methodology

- Acting as a marketplace for material alternatives

- Incentivizing suppliers to be more transparent

The platform allows material suppliers and intermediate component makers to feed third-party screened data to Material IQ where finished product manufacturers can view the profile in relation to relevant eco-label verification. Material IQ Profiles can also serve as chain of custody tracking, providing a consistent way to communicate design improvements, strengthen supply chain partners’ and key customers’ sustainability positions, and enable brands to step beyond compliance-based material assessment and into design optimization strategies.

Material IQ is currently in pilot stage. We are happy to speak with you about assessing your product’s material profile. For more information, explore the GreenBlue and Material IQ websites, or contact us.

Learn More About Material Hazards:

UNSAFE: The Truth Behind Everyday Chemicals

The Toxic Baby