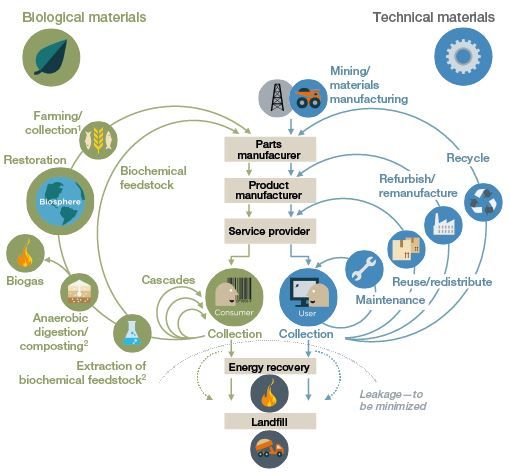

Representatives from Kimberly-Clark, MHG, Recycling Partnership, Braskem, and Printpack gathered on stage the last day of SPC Advance to discuss advancement of the circular economy through technologies and innovations. Braskem presented in conjunction with Printpack about their collaborations on bioplastic. Mikel Knight and Joe Jankowski presented the environmental benefits of bioplastics, including the lower carbon footprint than typical plastics and the recyclability. Ben Jarrett discussed Kimberly Clark’s use of wheat-straw (a wheat by-product) and bamboo as a feedstock for some of their paper products such as a line of toilet paper. Jarrett encouraged attendees to explore the LCAs comparing the associated impacts of the different feed stocks. For example the use of virgin and recycled fibers versus the use of bamboo fiber, or wheat-straw fiber

The last speaker on the panel was Keefe Harrison, Executive Director of the Recycling Partnership. Recycling might not a new technology or innovation, however, recycled material as a feedstock is a key element in advancing the circular economy. As Keefe Harrison stated:

“recycling is about developing feed stocks.”

Keefe places committed communities at the top of a list for “6 aspects of a healthy recycling system approach.”

“Local governments are the means by which recycled materials is captured within American communities,” said Harrison. “Local governments provide access to recycling to their residents. Whether that access is a drop-off location or curbside pick-up. When a government is capturing recyclables then they have a consistent feedstock supply.”

The important role of local governments was echoed throughout the conference. As expressed by several SPC Advance speakers, the variance in recyclable materials across regions, states and counties plays a major recycling challenge. Neighboring counties could accept different materials depending on where they are sending the material. Amy Duquette with HAVI Global Solutions spoke on how in her current position she will sometimes call up governments to discuss whether or not certain materials are accepted in their recycling systems. As a company that produces consumer packaging there is a sense of responsibility to create packaging that is recoverable. However, the recoverability can drastically change depending on the infrastructure, regulations, and access in an area. Cities such as Seattle are leading the way in recycling and composting efforts. Other municipalities can join by providing adequate access to recycling for their residents. The Recycling Partnership works to help municipalities scale up recycling efforts in communities.

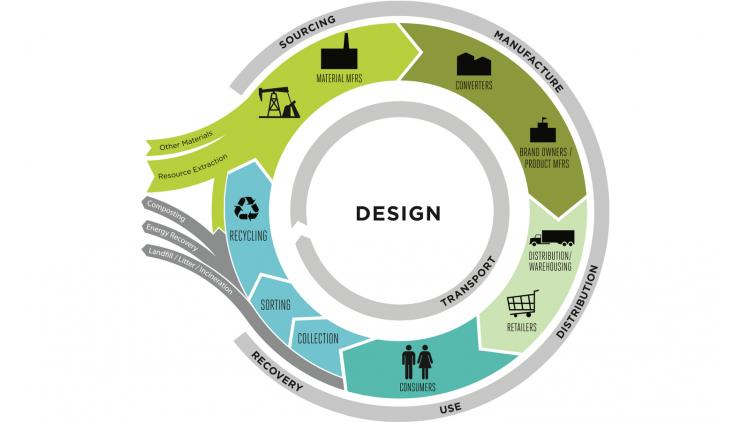

Increased recycling rates as well as the use of alternative materials will help lead the U.S. toward a circular economy.